Operation and maintenance

Our own teams in the field

Management of facilities

Evergaz operates its anaerobic digestion facilities and controls the production of biogas every day, while monitoring manufacturer warranties and the relations with biogas unit stakeholders.

- Receipt and storage of materials

- Storage and application of digestate

- Biogas production monitoring

- Thermal recovery monitoring

- Energy invoicing

- Management of contracts

- Monitoring of warranties

- Operational optimisation

By continually monitoring technological developments, we regularly optimise the operation of our units to ensure continuity of service and improve production efficiency. This often requires long-term investments in sites in operation with a view to improving the process, from the receipt of materials to the production of biogas and digestate.

Preventive maintenance

To avoid equipment damage, we have put in place preventive maintenance plans on our sites.

- Spare parts and stock management

- Emergency response and troubleshooting

- Resolution of non-compliances

Safety

Because the safety of our operating staff and visitors is our priority, Evergaz undertakes to implement preventive measures to protect everyone’s health and safety.

- Personal protection equipment

- Informing and raising awareness of the personnel

- First aid training

- Warning and intervention procedures

- Site marking and information

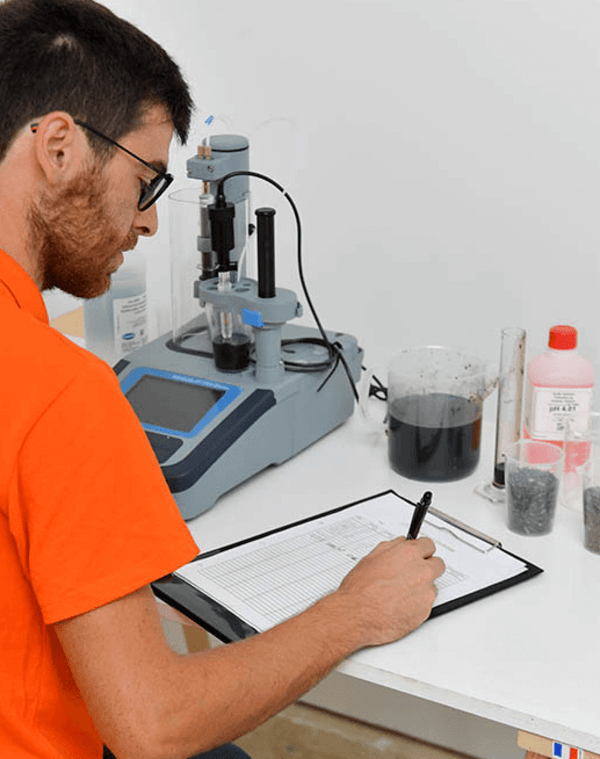

Biological monitoring

To guarantee the optimised operation of its anaerobic digestion units, we regularly analyse the methanogenic potential of the materials entering the anaerobic digestion unit, as well as the characteristics of the outgoing digestate. To this end, Evergaz’ design office, LEDJO Energie, has developed its own biological database, regularly enhanced by feedback, which now features more than 1,400 references.

- Input analysis

- Biological monitoring of digestate

- Performance analysis

Monitoring of regulatory developments

Our anaerobic digestion units are subject to ICPE regulations. Our teams constantly monitor regulatory developments in conjunction with the LEDJO Energie design office to ensure that our operations comply with applicable regulations and the mandatory regulatory declarations of the sites in operation.